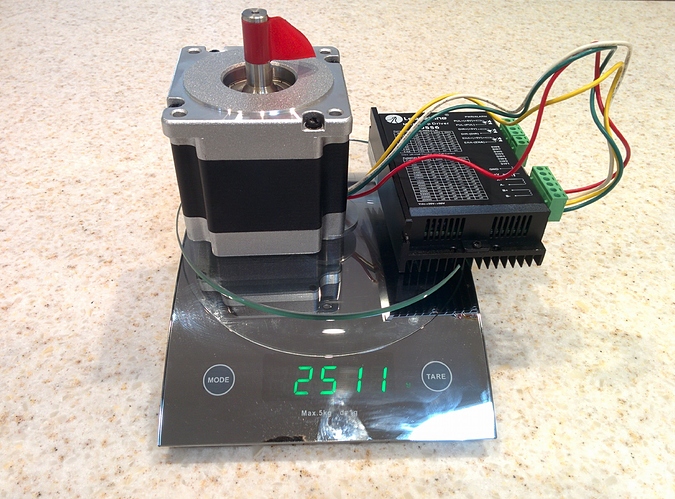

The working of this analog Stepper Motor Driver circuit is very simple. We will see a step – by – step working explanation.First, the 555 Timer IC is configured as an Astable Multivibrator i.e. it acts as a square wave generator.

Based on the position of the Potentiometer, the frequency of the square wave will vary anywhere between 7 Hz to 340 Hz.

This square wave is given to the CD4017 Counter IC as its Clock Input. For every positive transition of the clock signal i.e. a low to high transition, the counter output advances by one count.

For first positive transition on clock, Q0 will be high, for second positive transition, Q1 will be high and so on.

Since we need only 4 outputs, the fifth output i.e. Q4 is connected to the Reset pin so that the counter will reset and the counting starts once again.

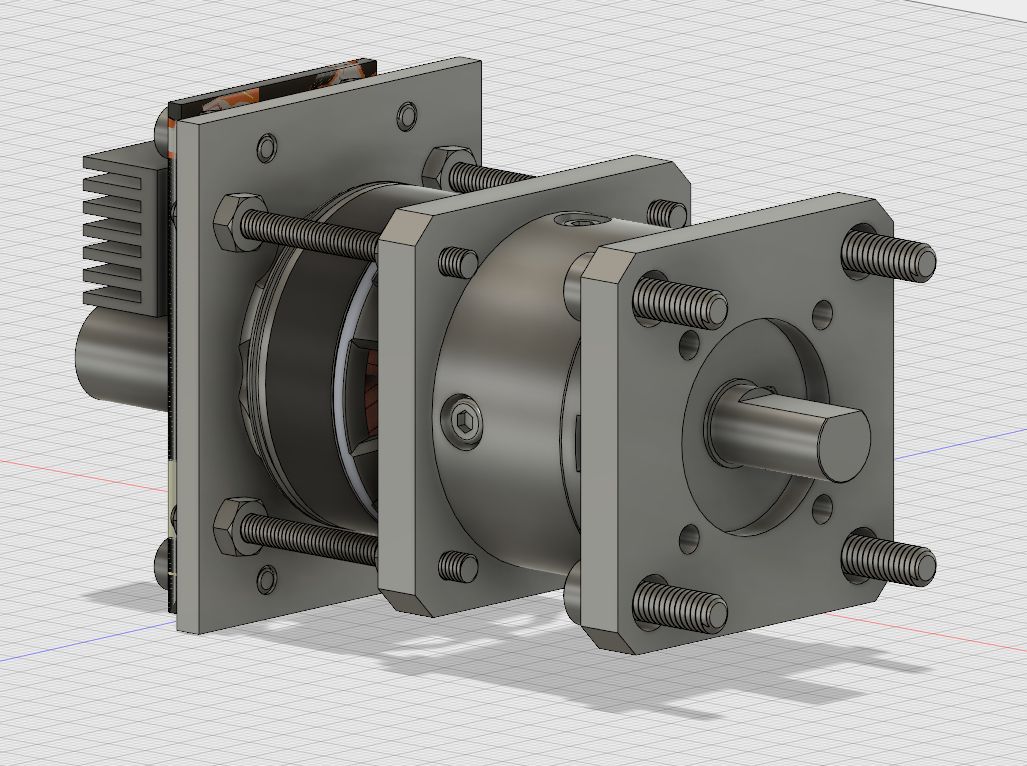

The outputs of the Counter IC CD4017 are given to 4 different transistor, which are in turn connected to the 4 coil terminals of the Stepper Motor. We can understand better from the following diagram.

Based on the position of the Potentiometer, the frequency of the square wave will vary anywhere between 7 Hz to 340 Hz.

This square wave is given to the CD4017 Counter IC as its Clock Input. For every positive transition of the clock signal i.e. a low to high transition, the counter output advances by one count.

For first positive transition on clock, Q0 will be high, for second positive transition, Q1 will be high and so on.

Since we need only 4 outputs, the fifth output i.e. Q4 is connected to the Reset pin so that the counter will reset and the counting starts once again.

The outputs of the Counter IC CD4017 are given to 4 different transistor, which are in turn connected to the 4 coil terminals of the Stepper Motor. We can understand better from the following diagram.

Assume the points A, B, C and D are the contacts of the coils connected to the transistors. The common wire in the stepper motor is given to 12V supply.

When the first clock signal is applied to the CD4017, Q0 becomes HIGH. This will turn ON the corresponding Transistor.

As a result, the supply from the common wire goes through point A to ground. This will energize the coil and acts as an electromagnet. The rotor will get attracted and turns to that position.

During the second clock pulse, output Q1 become HIGH and as a result, the transistor associated with it is turned ON. Now, the current flows from common wire to GND through point B.

Hence, this coil will be energized and turns in to an electromagnet. This will further rotate the rotor. This process continues and depending on the frequency of the clock signal, the speed of rotation of the stepper motor varies.

Advantages

A DIY type Stepper Motor Driver is designed here that can drive Unipolar Stepper Motors.

By using this stepper motor driver, we can avoid costly dedicated Stepper Motor Driver boards.

Disadvantages

This design is not an efficient one.

Requires a lot of complex wiring for a small application.